Redesign Saved Costs While Maintaining Performance

Before

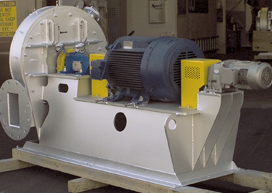

After

Applications

High temperature process fans.

Challenge

The original customer-specified unit design was over-engineered, creating manufacturing inefficiencies and many unnecessary costs.

Solution

IB International’s technical staff examined the customer-designed plans and immediately identified significant product improvement possibilities. By eliminating the centerline support, adding a turning gear instead of the original bypass feed, and changing the seal to a simpler design, a much more cost-effective solution was delivered, without sacrificing performance.

Benefits

IB International’s proactive redesign of this system ultimately represented a 30% customer savings. In addition, the new system had a reduced footprint for better space utilization and a simpler design for easier maintenance.